Piston Seal and Rod Seal

Type Spring Energized Seals

Dynamic applications that are required to function without lubrication put a greater emphasis on seal design and the materials being used. Especially in the case of dry running rod seals which are subject to high temperature high pressure conditions, PTFE compounds combined with advanced fillers must be selected in order to achieve efficient performance and a long service life.

Advanced polymer technology combined with many years of practical experience allow our team of engineers to select the correct combination of material and seal geometry for the application in question.

Often reciprocating but also in rotary installations, maintaining a high level of seal efficiency by minimising wear allows our seal solutions to achieve outstanding levels of performance and longevity.

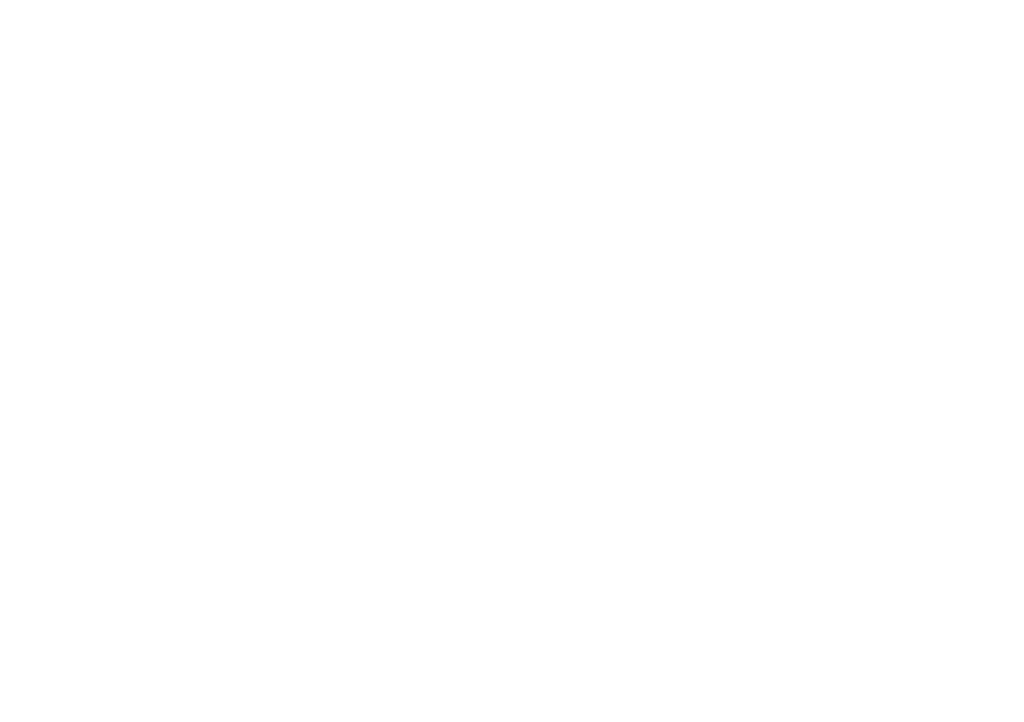

URI – PTFE Rod Seal

For fluids.

With sharp-edged sealing lip on the internal diameter

for good wiping effect with rod seals.

Operating limits

T = –75°C to +300°C

p = up to 250 bar

v = 15 m/s ⇔

Standard Type URI

Preferential Range

Ordering example: URI – B12 – 332 – HS 21059 – C

URI = type “rod seal”

B12 = rod Ø 12

332 = nominal cross-section

HS 21059 = casing material

C = spring material

Standard Rod Sizes and Housing Dimensions

| Rod-∅ | Groove-∅ | Housing Dimensions |

|---|---|---|

| Bf7 | AH9 | G+0,2 |

| 3 | 5,84 | 2,4 |

| 4 | 6,84 | 2,4 |

| 5 | 7,84 | 2,4 |

| 6 | 8,84 | 2,4 |

| 8 | 10,84 | 2,4 |

| 8 | 12,52 | 3,6 |

| 10 | 14,52 | 3,6 |

| 12 | 16,52 | 3,6 |

| 14 | 18,52 | 3,6 |

| 16 | 20,52 | 3,6 |

| 18 | 22,52 | 3,6 |

| 19 | 23,52 | 3,6 |

| 20 | 24,52 | 3,6 |

| 20 | 26,14 | 4,7 |

| 22 | 28,14 | 4,7 |

| 24 | 30,14 | 4,7 |

| 25 | 31,14 | 4,7 |

| 28 | 34,14 | 4,7 |

| 32 | 38,14 | 4,7 |

| 36 | 42,14 | 4,7 |

| 40 | 49,44 | 7,1 |

| 45 | 54,44 | 7,1 |

| 50 | 59,44 | 7,1 |

| 56 | 65,44 | 7,1 |

| 63 | 72,44 | 7,1 |

| 70 | 79,44 | 7,1 |

| 80 | 89,44 | 7,1 |

| 90 | 99,44 | 7,1 |

| 100 | 109,44 | 7,1 |

| 110 | 119,44 | 7,1 |

| 125 | 137,10 | 9,5 |

| 140 | 152,10 | 9,5 |

| 160 | 172,10 | 9,5 |

| 180 | 192,10 | 9,5 |

| 200 | 212,10 | 9,5 |

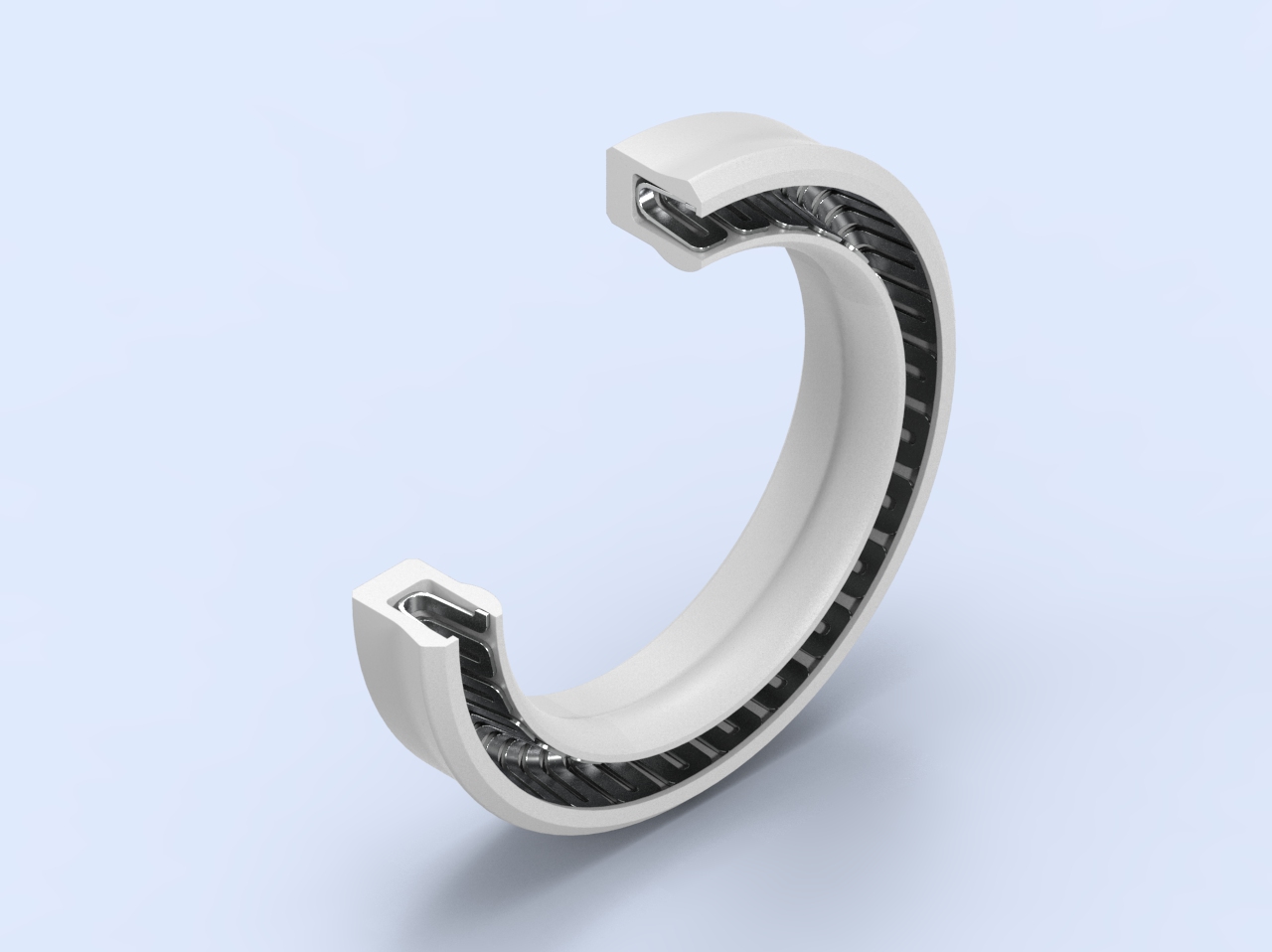

URA – PTFE Piston Seal

For fluids.

With sharp-edged sealing lip on the external diameter

for good wiping effect with piston seals.

Operating limits

T = –75°C to +300°C

p = up to 250 bar

v = 15 m/s ⇔

Standard Type URA

Preferential Range

Ordering example: URA – A50 – 316 – HS 21037 – C

URA = type “piston seal”

A50 = cylinder Ø 50

316 = nominal cross-section

HS 21037 = casing material

C = spring material

Additional diameters/sizes from 2 to 3,000 mm

available on request

Standard Cylinder Sizes and Housing Dimensions

| Cylinder-∅ | Groove-∅ | Housing Dimensions |

|---|---|---|

| AH9 | Bf7 | G+0,2 |

| 8 | 5,16 | 2,4 |

| 10 | 7,16 | 2,4 |

| 12 | 9,16 | 2,4 |

| 14 | 9,48 | 3,6 |

| 16 | 11,48 | 3,6 |

| 18 | 13,48 | 3,6 |

| 20 | 15,48 | 3,6 |

| 22 | 17,48 | 3,6 |

| 24 | 19,48 | 3,6 |

| 25 | 20,48 | 3,6 |

| 25 | 18,86 | 4,7 |

| 28 | 21,86 | 4,7 |

| 30 | 23,86 | 4,7 |

| 32 | 25,86 | 4,7 |

| 36 | 29,86 | 4,7 |

| 40 | 33,86 | 4,7 |

| 50 | 40,56 | 7,1 |

| 60 | 50,56 | 7,1 |

| 63 | 53,56 | 7,1 |

| 70 | 60,56 | 7,1 |

| 80 | 70,56 | 7,1 |

| 100 | 90,56 | 7,1 |

| 125 | 112,90 | 9,5 |

| 140 | 127,90 | 9,5 |

| 160 | 147,90 | 9,5 |

| 180 | 167,90 | 9,5 |

| 200 | 187,90 | 9,5 |

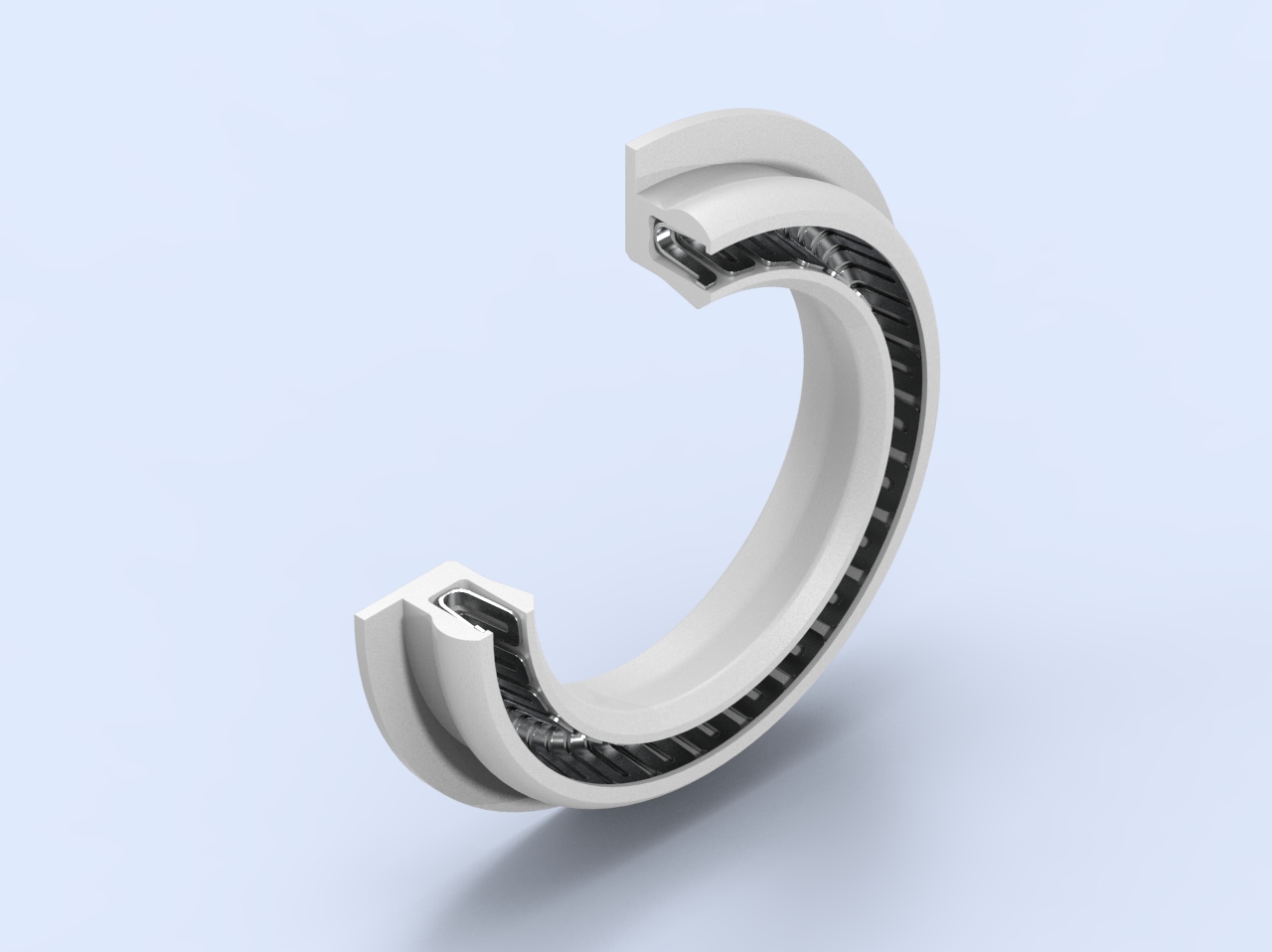

URF – Rod Seal

With clamping flange for sealing rotary and

swiveling applications.

Operating limits

T = –75°C to +300°C

p = up to 250 bar

v = 15 m/s ⇔

v = 2.5 m/s

Standard Type URF

Preferential Range

Ordering example: URF – B20 – 108 – HS 21037 – C

URF = type “shaft seal”

B20 = shaft Ø 20

108 = nominal cross-section

HS 21037 = casing material

(for other compounds see compound table)

C = spring material

Additional diameters/sizes from 2 to 3,000 mm

available on request

Standard Shaft Sizes and Housing Dimensions

| Shaft-∅ | Groove-∅ | Housing Dimension |

|---|---|---|

| Bf7 | AH9 | G1 min |

| 3 | 5,84 | 2,4 |

| 5 | 9,52 | 3,6 |

| 6 | 10,52 | 3,6 |

| 8 | 12,52 | 3,6 |

| 10 | 14,52 | 3,6 |

| 12 | 16,52 | 3,6 |

| 14 | 18,52 | 3,6 |

| 16 | 20,52 | 3,6 |

| 18 | 22,52 | 3,6 |

| 20 | 26,14 | 4,7 |

| 22 | 28,14 | 4,7 |

| 24 | 30,14 | 4,7 |

| 25 | 31,14 | 4,7 |

| 28 | 34,14 | 4,7 |

| 30 | 36,14 | 4,7 |

| 32 | 38,14 | 4,7 |

| 35 | 41,14 | 4,7 |

| 36 | 42,14 | 4,7 |

| 40 | 49,44 | 7,1 |

| 42 | 51,44 | 7,1 |

| 45 | 54,44 | 7,1 |

| 50 | 59,44 | 7,1 |

| 56 | 65,44 | 7,1 |

| 60 | 69,44 | 7,1 |

| 63 | 72,44 | 7,1 |

| 70 | 79,44 | 7,1 |

| 80 | 89,44 | 7,1 |

| 90 | 99,44 | 7,1 |

| 100 | 109,44 | 7,1 |

| 110 | 119,44 | 7,1 |

| 120 | 129,44 | 7,1 |

| 125 | 137,10 | 9,5 |

| 130 | 142,10 | 9,5 |

| 140 | 152,10 | 9,5 |

| 160 | 172,10 | 9,5 |

| 180 | 192,10 | 9,5 |

| 200 | 212,10 | 9,5 |

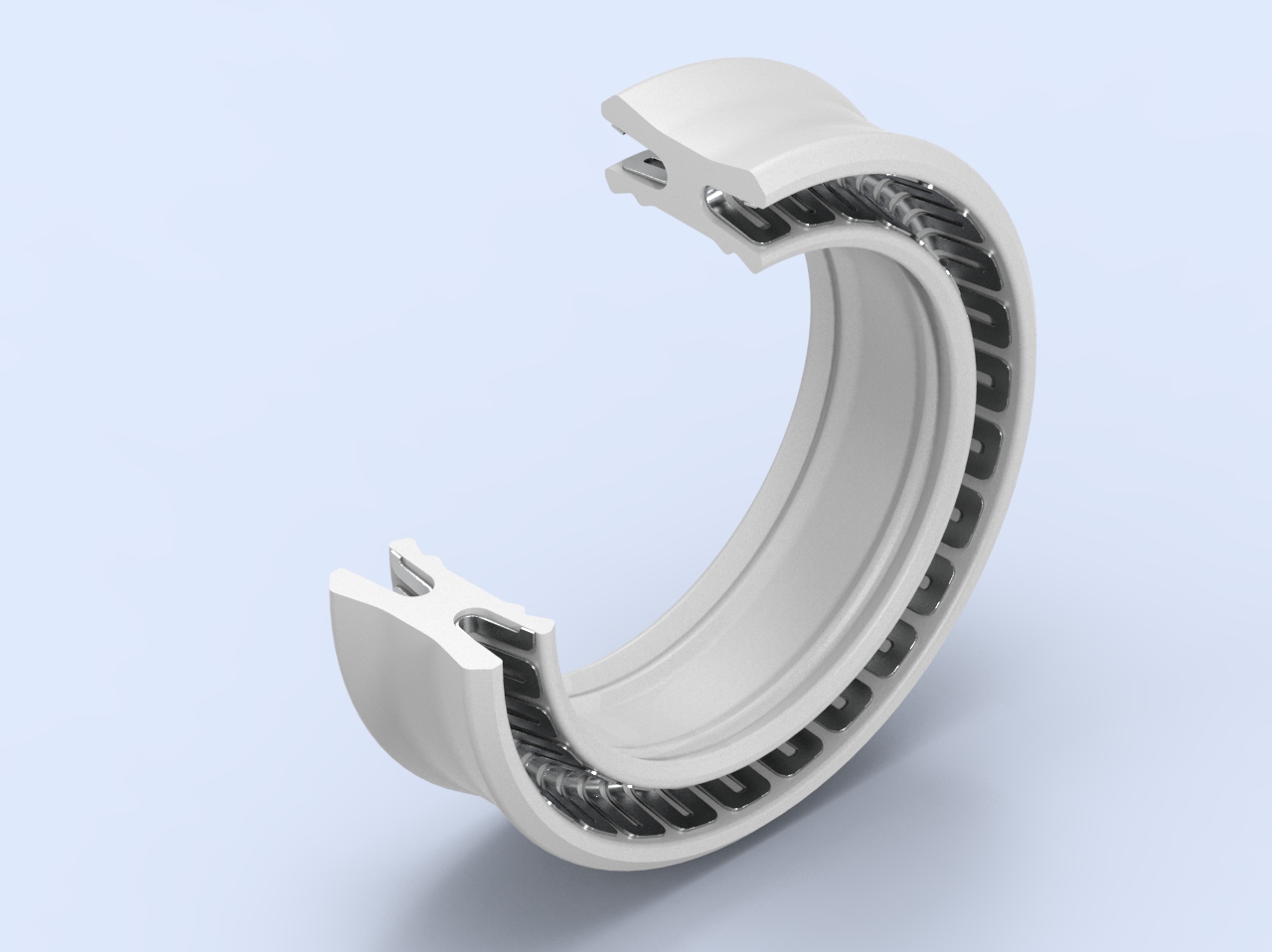

Examples of Other Types

Spring Energized Seals for Automotive Applications

Factsheet: Spring Energized Seals for alternate Automotive Applications