PTFE Bellows

Customized Design and Performance

PTFE bellows are used, for example, as compensating elements between engineered parts. By specifically using different fold geometries, any combination of properties can be achieved as required—for example, high flexibility or compressive strength.

The outstanding material properties of Polytetraflon®-PTFE allow bellows to be used increasingly in the medical and food sectors, as well as in general industry.

Essential Advantages:

- Almost universal chemical resistance

- FDA conformity for food and pharmaceutical products

- Highly suitable for sterilization

- Antiadhesive behavior

- Large temperature range of –60°C to +200°C

- Cost-effective series production from semifinished product to final product

- High reverse bending strength

- Good dimensional stability

- Low tooling costs

- Freedom of design

Application Examples:

- As compensation for expansion in pipe systems

- For shielding sterile areas

- Filling lines

- Aseptic valves

- Solenoid valves

- Metering devices

- Pumps and valves, coating technology, steel mills, fitting industry

PTFE Bellow Types

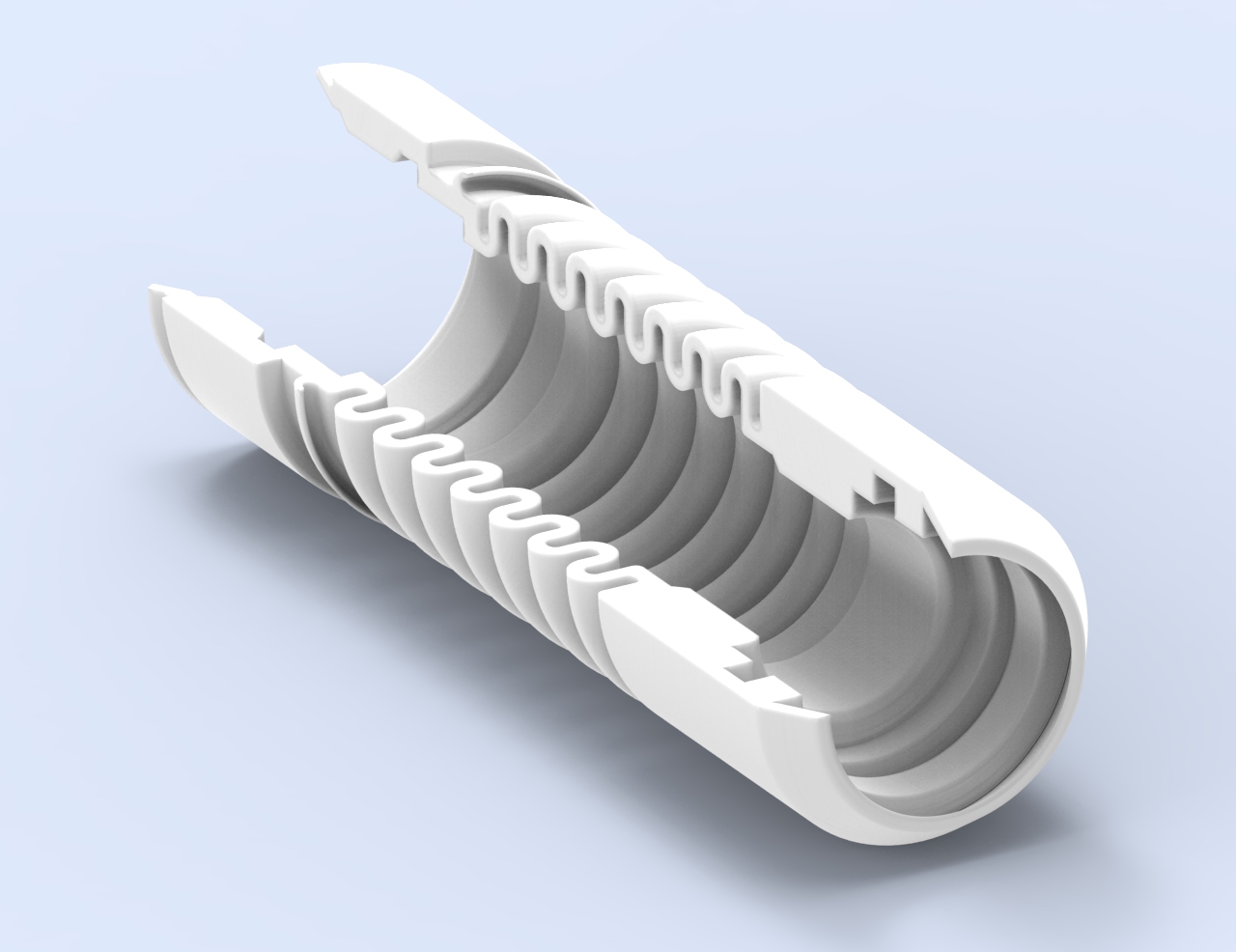

Bellow for solenoid valve

For use in medical engineering. High flexibility and frequency. Physiologically harmless. Resistant to aggressive cleaning agents.

Bellow for filling valve

Hermetic separation of the medium from the actuation mechanism. The tip is the sealing cone of the valve.

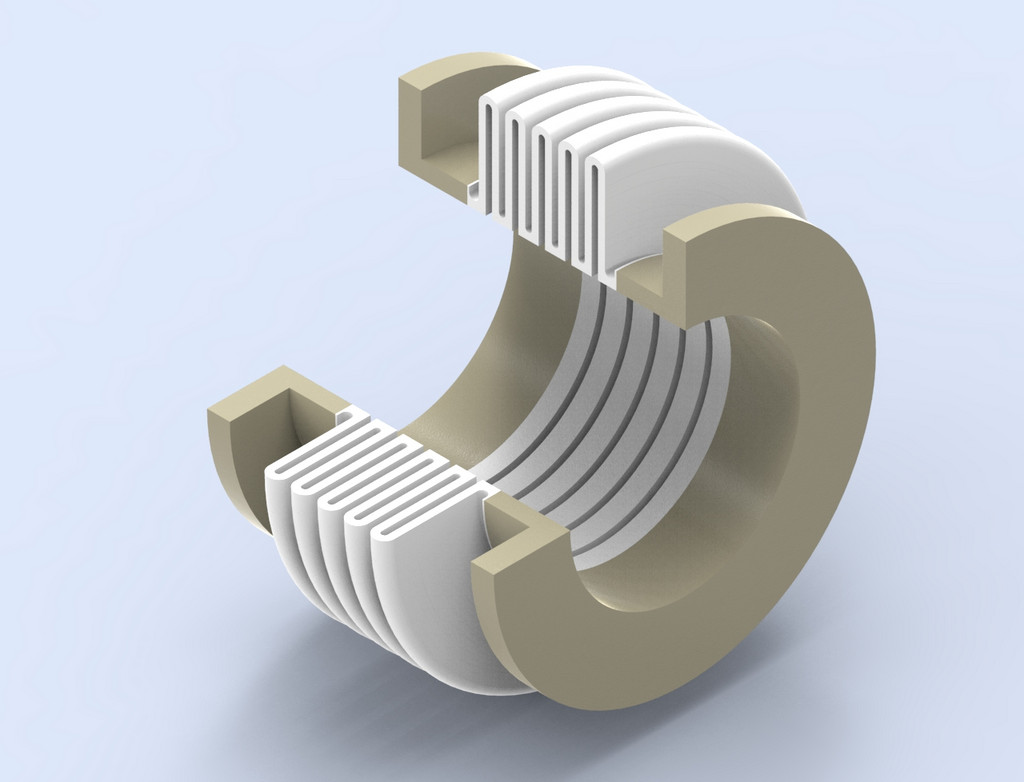

Multifunctional bellow

Separation of two areas with moving parts. Integration of sealing and guiding elements. Connections can be designed according to customer specifications.

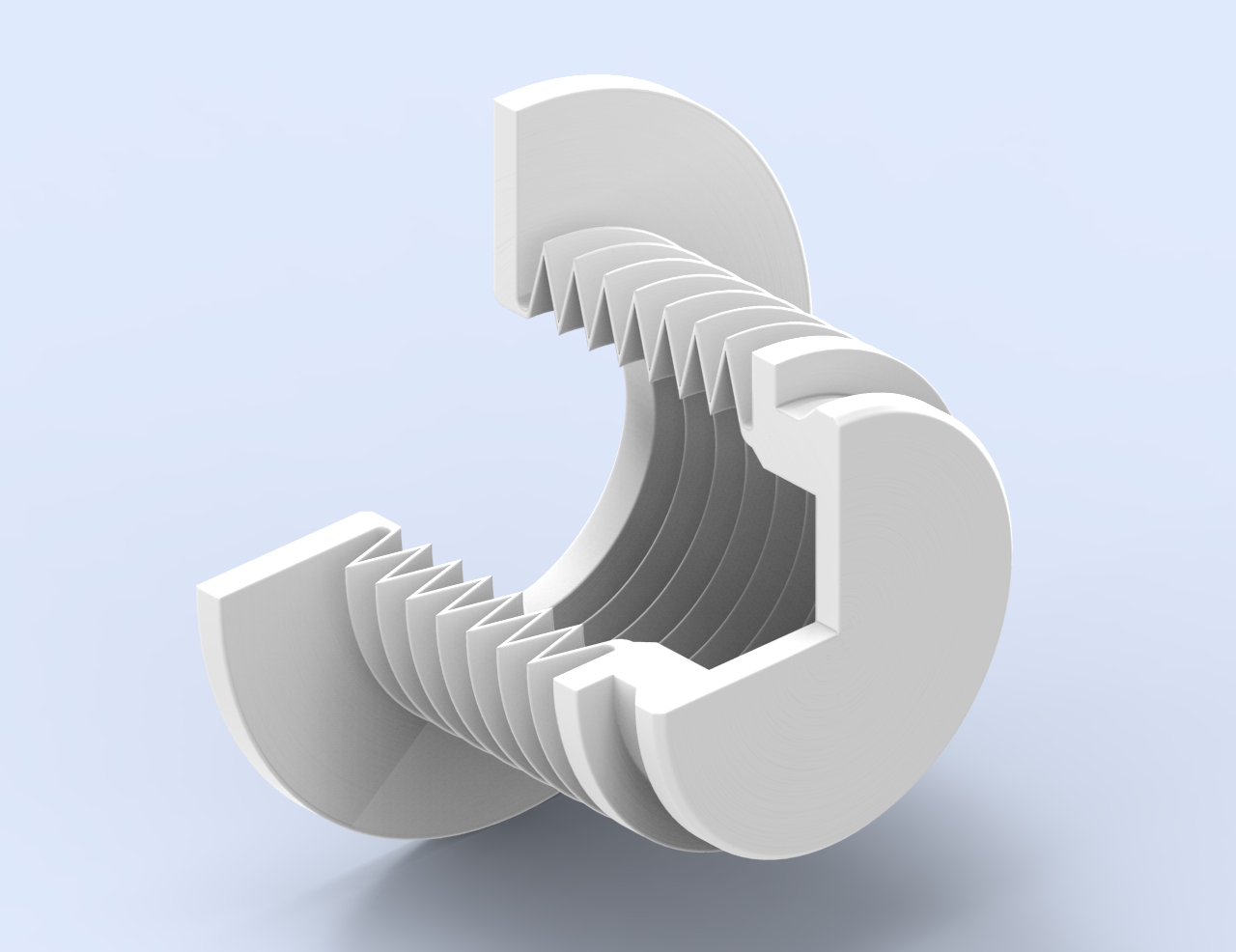

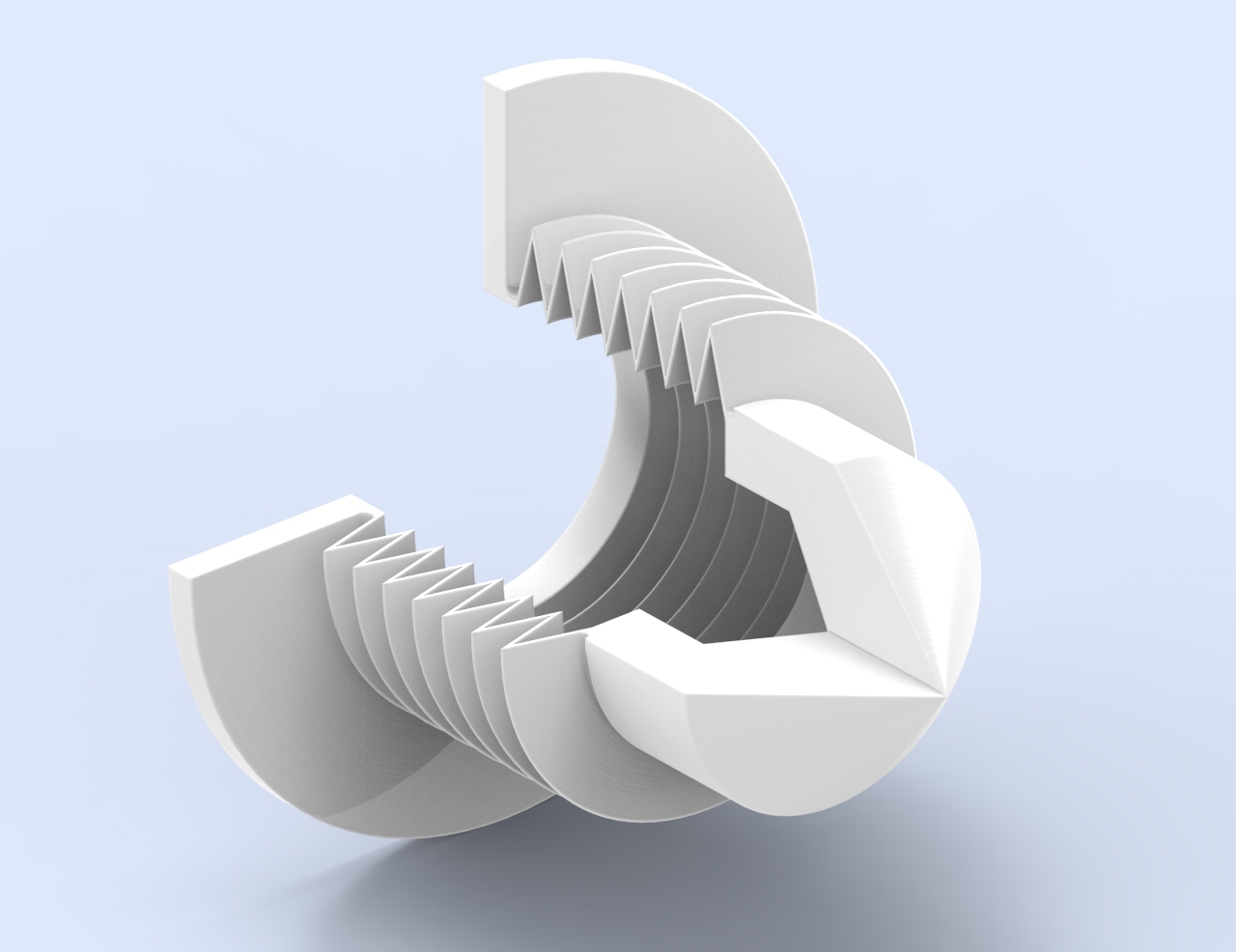

Fold Types

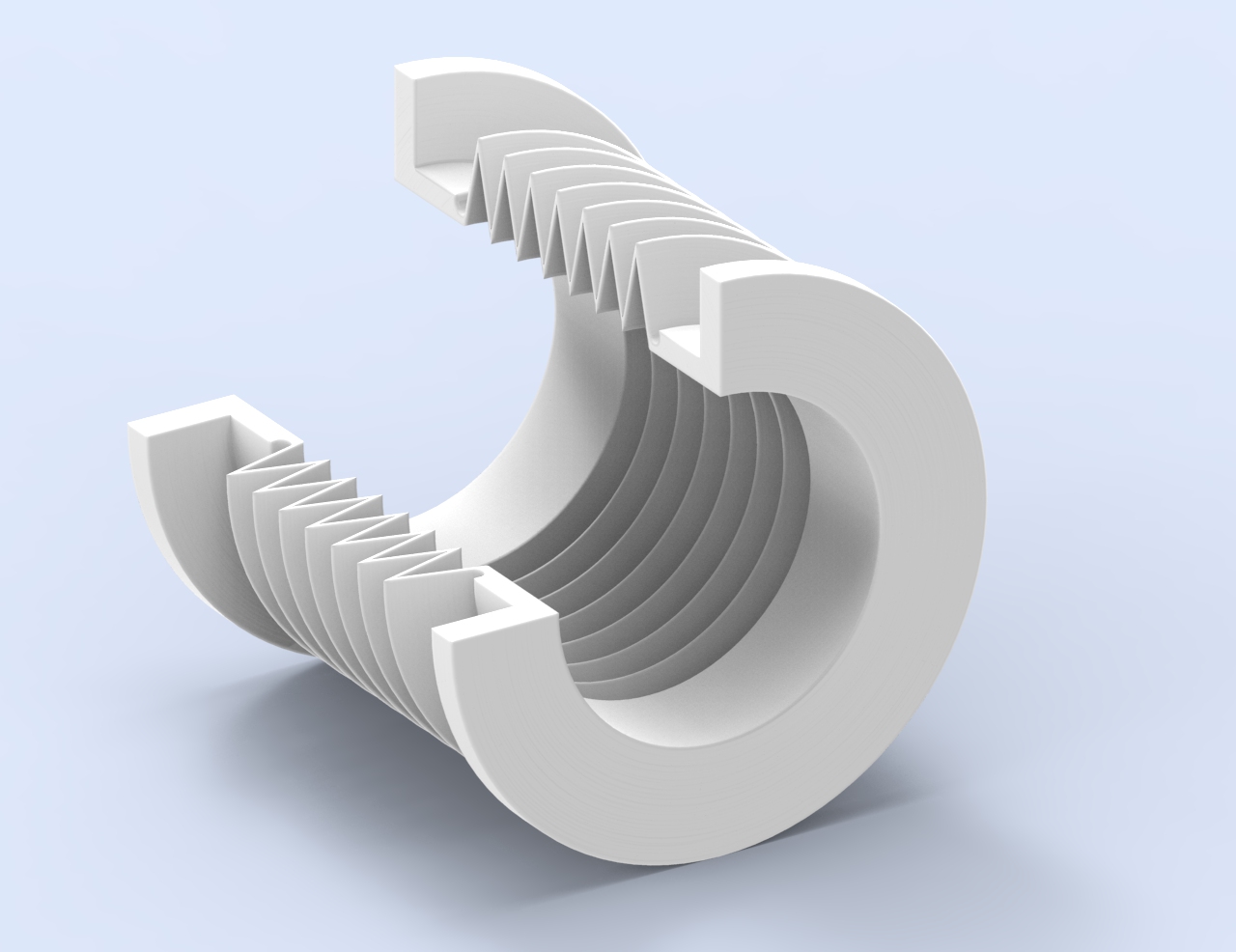

Pointed, non-cut folds

For maximum expansion and low pressures up to 3 bar.

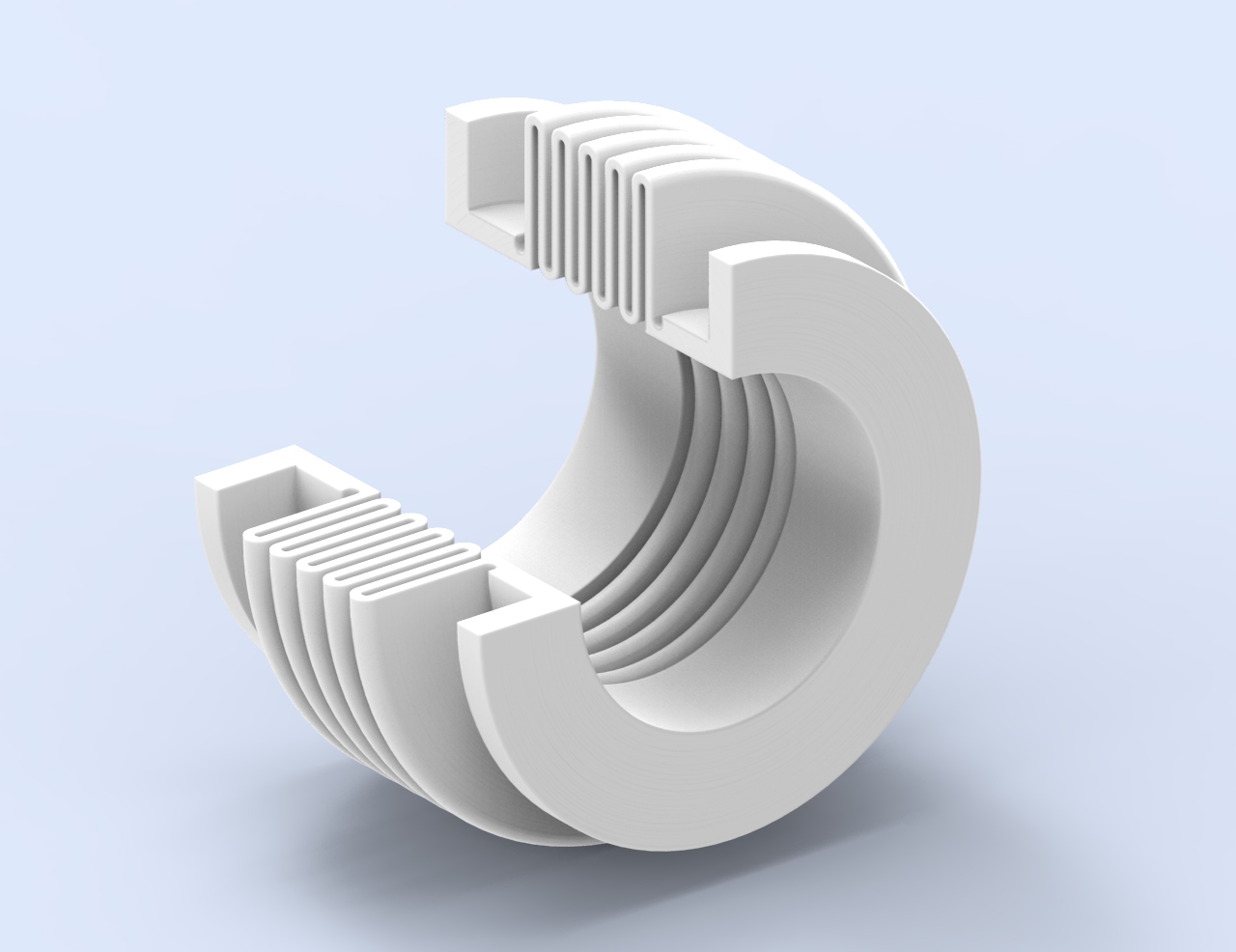

Round, machined folds

For improved cleaning and maximum reverse bending strength. Low to medium pressures up to 6 bar.

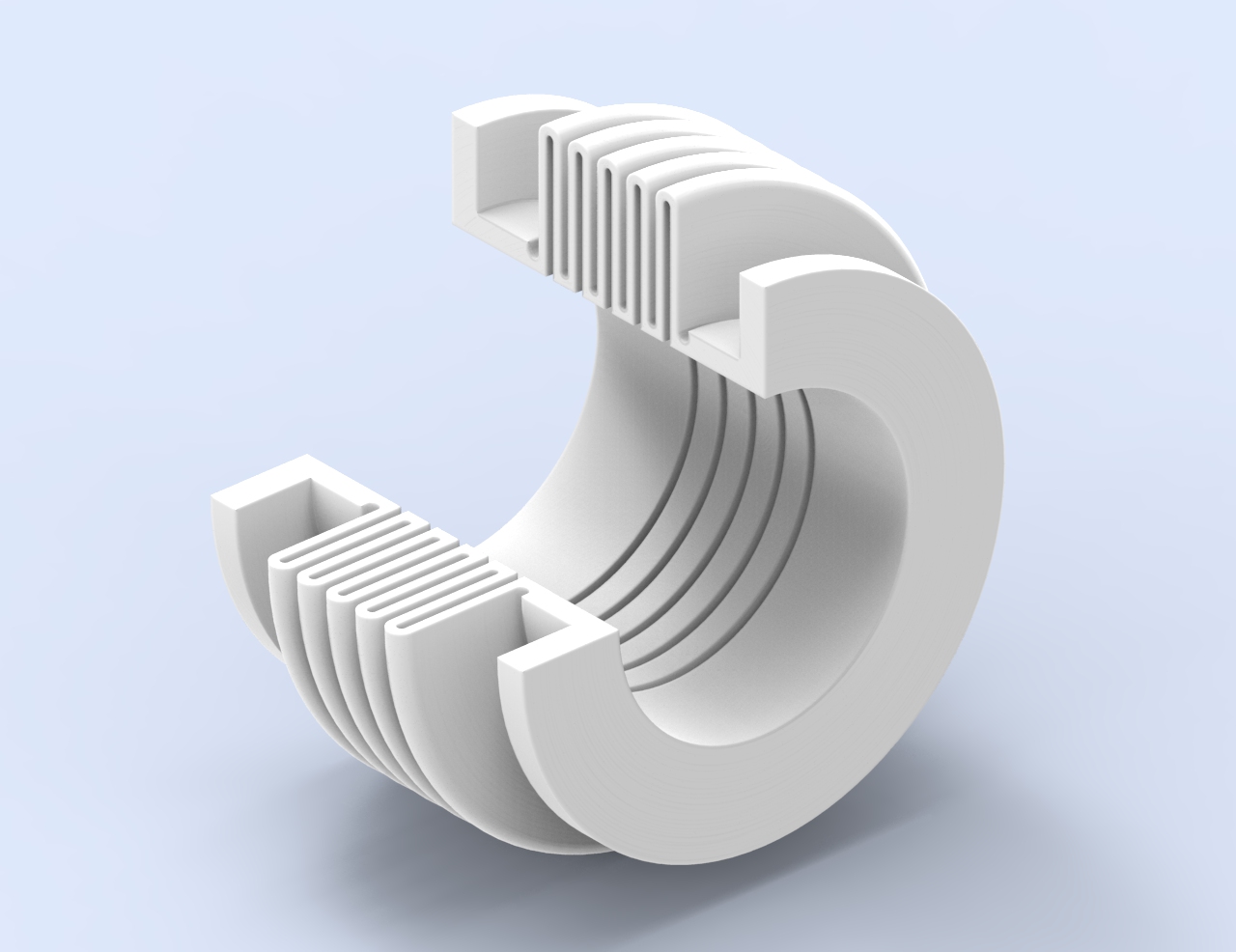

Solid, machined folds

For high pressures above 6 bar. Optimal with rectangular support on the rod or in the cylinder bore.